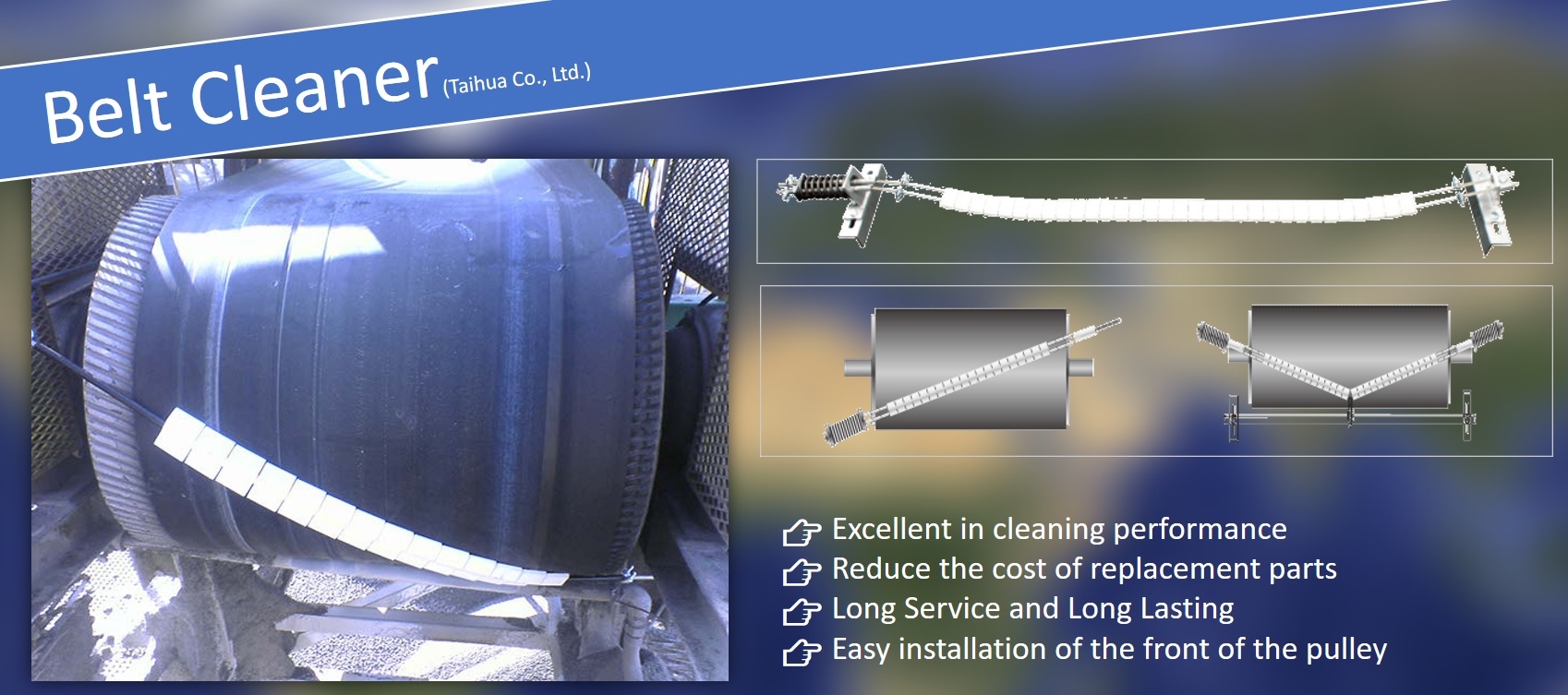

Belt Cleaner

Totally different from the conventional structures, our ceramic belts is the newest type of belt scraper already developed up to today. For remove tailing on the surface of the encrusted belts carrying material, our belt cleaner technology systems help bulk materials handling facilities accomplish their goals for safety, cleanliness, environmental compliance and operation efficiency.