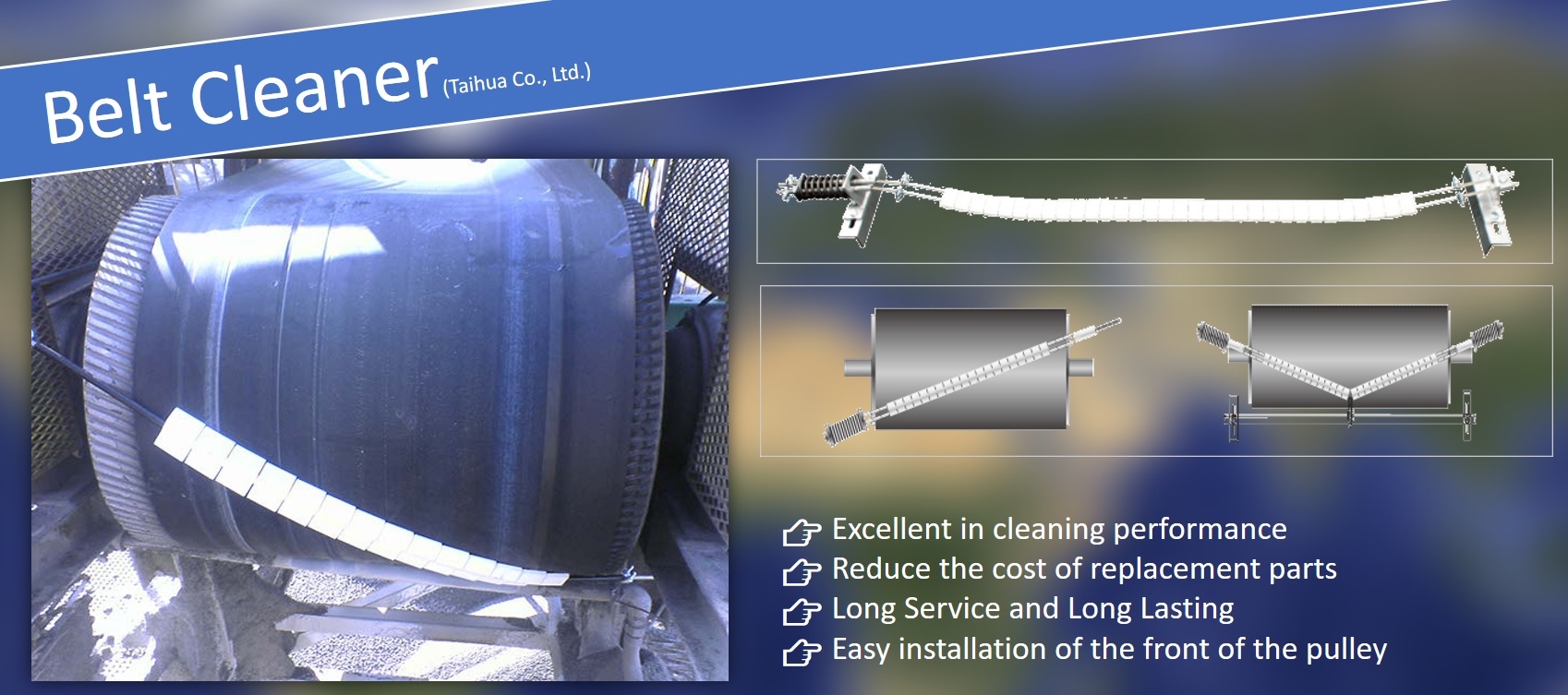

Totally different from the conventional structures, our ceramic belts is the newest type of belt scraper already developed up to today. For remove tailing on the surface of the encrusted belts carrying material, our belt cleaner technology systems help bulk materials handling facilities accomplish their goals for safety, cleanliness, environmental compliance and operation efficiency.

Advantages of the use:

- Easy installation of the front of the pulley

- Excellent in cleaning performance

- Reduce the cost of replacement parts

- Increase the life of belts

Our crews have the tools, the training, and experience to shorten the learning curve and meet your requirements. Our engineered components will improve performance and reduce spillage and airbone dust. And engineered flow transfer chutes help material handling operations achieve new standards of excellence.

The Features of the Conventional Tip Belt Cleaner

In the conventional tip belt cleaner, a gap was produced between the tip and the belt so that the belt cleaner could not work properly. It also took time to install and adjust the belt cleaner on site.

High performance and quality of the layers of tiles, shown that there is no need for more of a scrapers for conveyor belt.

Today are installed primary and secondary scrapers for an efficient cleaning of quality, however, trade and sudden stops that upset production.

Our belt cleaner reduce costs and maintenance, have long life, high performance, easily to install and most importantly no need to install more than one.

The efficacy of the cleaning is superior by the persistence of the power of abrasion from the chips. The structure of ceramic and metal is resistant in the face of low and high temperature,otherwise it is installation is extremely easy.

The new belt cleaner is positioned in the front part of the head pulley. Our scraper were developed to act as efficient system for cleaning of waste materials and aggregates. Waste sent to the pipeline or chute means more cleaning along the belt and reducing overall costs.The belt scraper of the diagonal has the function to be installed in smaller belts of 60 mm to 1.20 mm in length. Our belt cleaner in V is installed on conveyor belts for larger size of 1.20 mm to 1.60 mm in length, were developed to clean with maximum efficiency to the waste materials.

Our belt cleaner is durable and can normally maintain its cleaning power in 24 hours operation for one year or longer (the abrasion rate of the tip varies depending on a conveyed object).

The belt cleaning is installed from the axis of the conveyor belt,until bottom of the belt apart,demonstrating the efficacy of cleaning.

- Very easy to install and can be installed in a short time

- Suitable for cleaning a dry, block, wet, powder, sticky, or high temperature object

- High cleaning power. Tips are installed with an angle to clean up a conveyor belt sharply

- Light weight. Our belt cleaner (W = 900) is approximately 9 Kg in weight

- Long service life. Approx. 10 months for sinter, approx. 15 months for limestone, approx. 15 months for coal, approx. 10 months for iron ore

- Ceramic tips closely contact with a conveyor belt for cleaning even if the belt is worn in the center or a crowned pulley is used to drive the belt

Newly improved spring tension ed and fixed side holders are shown in photos at the upper left and right sides, respectively. With the new holders, the belt cleaner becomes easier to install than conventional belt cleaners and its wire becomes adjustable individually. In addition, the ceramic tips can contact with a conveyor belt more closely to improve the cleaning efficiency.