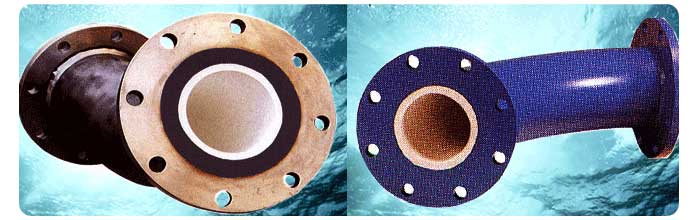

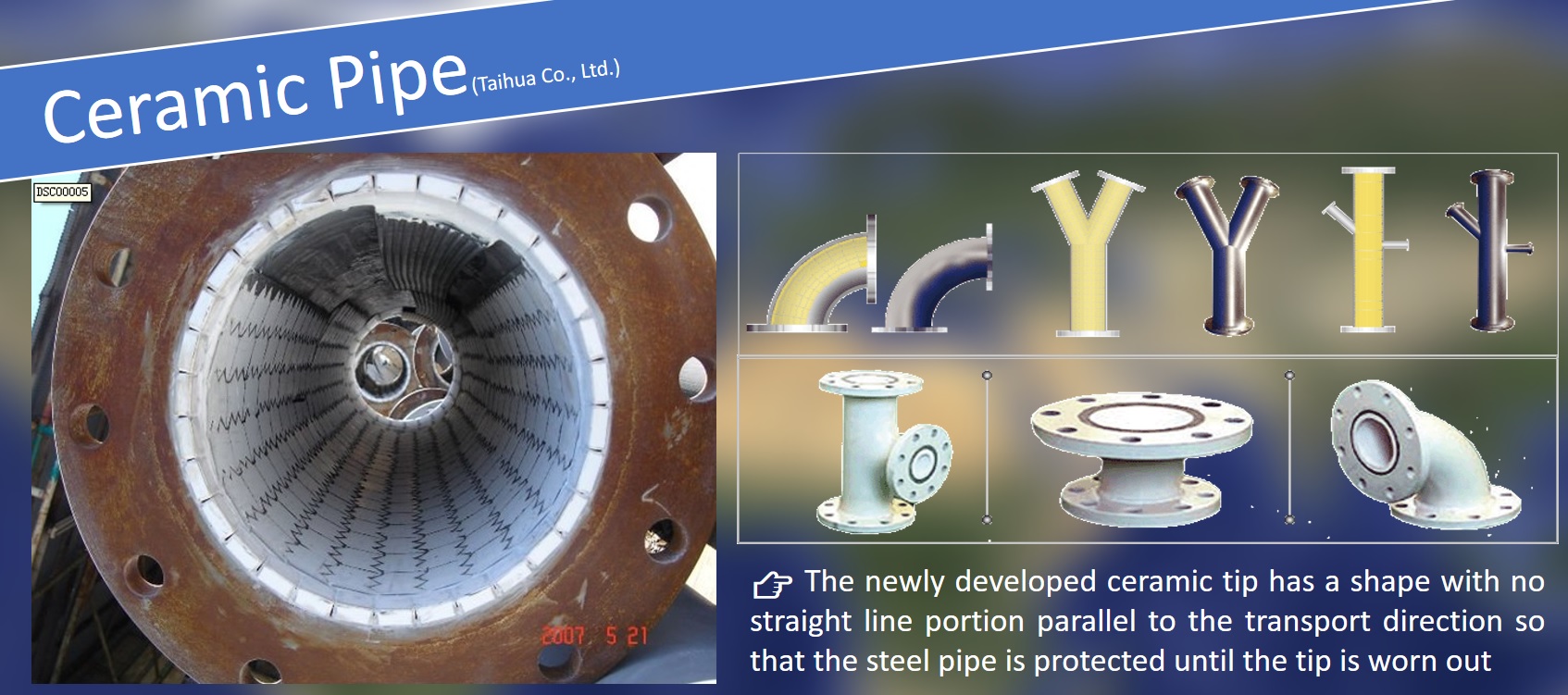

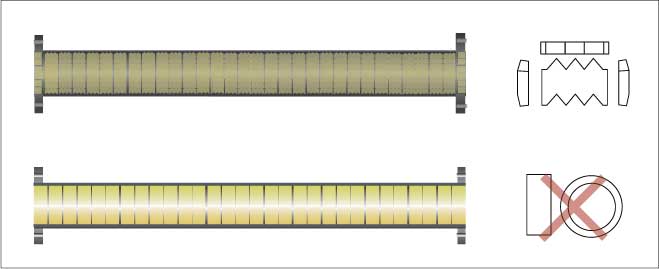

Our ceramic pipe has a characteristic in its new shape of a ceramic tip for which we have applied for a patent. A conventional ceramic tip was arranged with a certain gap between tips in a steel pipe so that the pipe was damaged at the gap before the tip was worn out. The newly developed ceramic tip has a shape with no straight line portion parallel to the transport direction so that the steel pipe is protected until the tip is worn out.

The tailing that are in the pipeline hydraulic transport, which are the phenomena known as the wear abrasion, fatigue, impact. Have seen that, the use of a tube is 6mm in length, the pipe wall thickness was 20mm, and after 8 months of using, the bottom is corroded till the pipe has 1mm of thickness. Our pipe line has the advantage of 3mm to 4mm of thickness after 12 months of use, ten times more than life to the pipe. Guaranteed protection against abrasion. The direction of alignment of ceramics in zig zag have excellent resistance to friction of abrasive agents such as sand, gravel, tailing with solid particles, scale, coal, pulp, tailing from phosphate, salt slag, sludge, ash, ....

With our new production method, it has become possible to install our unique shaped ceramic tip in a long and unreachable steel pipe. The abrasion resistance of the ceramic pipe is approximately three times than that of the conventional products. Also, a specially processed flange is used in the steel pipe to optimize the characteristics of the ceramic tip.

A-20mm B-eight mounth of use C-shares worn

The zig zag ceramic alumina pressure has superior performance against abrasion which has five times more resistant than the conventional ceramic. If the objective is protection of components and reduced maintenance costs, the correct application of anti-abrasive lining led immediately to track the economy. Our ceramic pipe lining of hydraulic and pneumatic conveying transport has efficiency and economy, especially in steel tubes. Where they have great advantages, increasing the time of life.

Therefore these sites,the curves,are lining internally against abrasion,including the firt segment straight after leaving the region.

Due to its zigzag shape, the ceramic tip does not produce a groove parallel to the transport direction so that the steel pipe is protected until the tip is worn out. The press molded ceramic tip has more than 4 times higher abrasion resistance than a cast-molded ceramic tip; however, it is quite high in price. Our ceramic pipe has been provided at a low price by performing all production processes internally.

A liner can be installed over whole area in an elbow pipe. However, it is quite effective just by installing the liner to approximately 75% of internal surface of the steel pipe, especially around the outer corner of high abrasion. The required lining area is different depending on the transported object and rate.